Metal Roof Panels - 6 Things to Consider when Purchasing

christine • January 20, 2020

Texas' Favorite Roof Type

Get A Free Quote Today!

From appearance, to value and durability—a metal roof has much more to offer your home than its competition. There is nothing that can erode the value of your home more quickly than a leaking roof. Metal roofs last longer and are better at protecting your home from the elements than standard asphalt shingles. Metal roofs have even protected homes from brush and forest fires. Today, many people are choosing metal roof panels for their beauty, durability, and environmentally-friendly qualities.

A metal roof will last you typically about 50 years, longer than other roofing materials. You can install a metal roof on a home, garage, barn, or any other structure that you wish. Putting a new roof on your home is always a considerable expense—no matter what the material you use. But with a metal roof, there is the real possibility that you will never have to replace your roof again your lifetime.

When you consider that a metal roof can last many times longer than other roofing options, it’s clear that metal roofing is the most affordable roofing solution on the market on a price-per-year basis. There are many things to know about metal roof panels that will help orient you as you make your decision about purchasing the best roofing material for your structure.

6 Things To Consider When Purchasing Metal Roof Panels

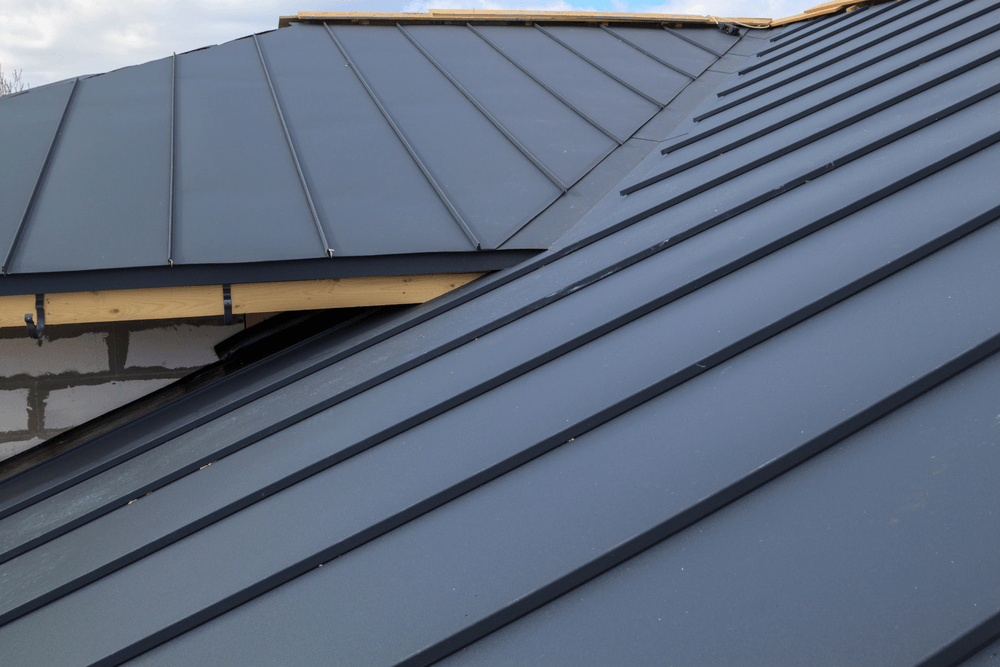

Roof pitch is defined as the steepness of your roof. Roof pitch is usually given as a ratio with 12 in the denominator. The top number indicates how much the roof rises in 12 inches of depth. A 45-degree roof would have a pitch of 12/12.

Most roofs are somewhere between 4/12 and 9/12. Steep roofs prevent the accumulation of debris, but they can be more dangerous to work on. The pitch of your roof can determine which type of roof panel is ideal for your home—as well as which locking mechanism is best.

Gauge is the unit of measurement for sheet metal thickness. It is a traditional, non-linear system that was developed in 19th century England as a measurement system for items like needles and wire. Counter to intuition, the smaller the gauge number for a piece of sheet metal, the thicker it is.

For your metal roof, you want a gauge that’s thick enough to be durable but thin enough to be light and workable. The standard industry gauge size for roofing is 24 and 26 gauge panels. These equate to approximately 0.025 and 0.0188 inches, respectively.

To put it in a context that is easier to understand, the sheet metal panels on your roof are about as thick as six standard pieces of copy paper stacked on top of each other. This is an ideal width to provide maximum protection while still ensuring the panels are light enough to work with and not stress the roof with their weight.

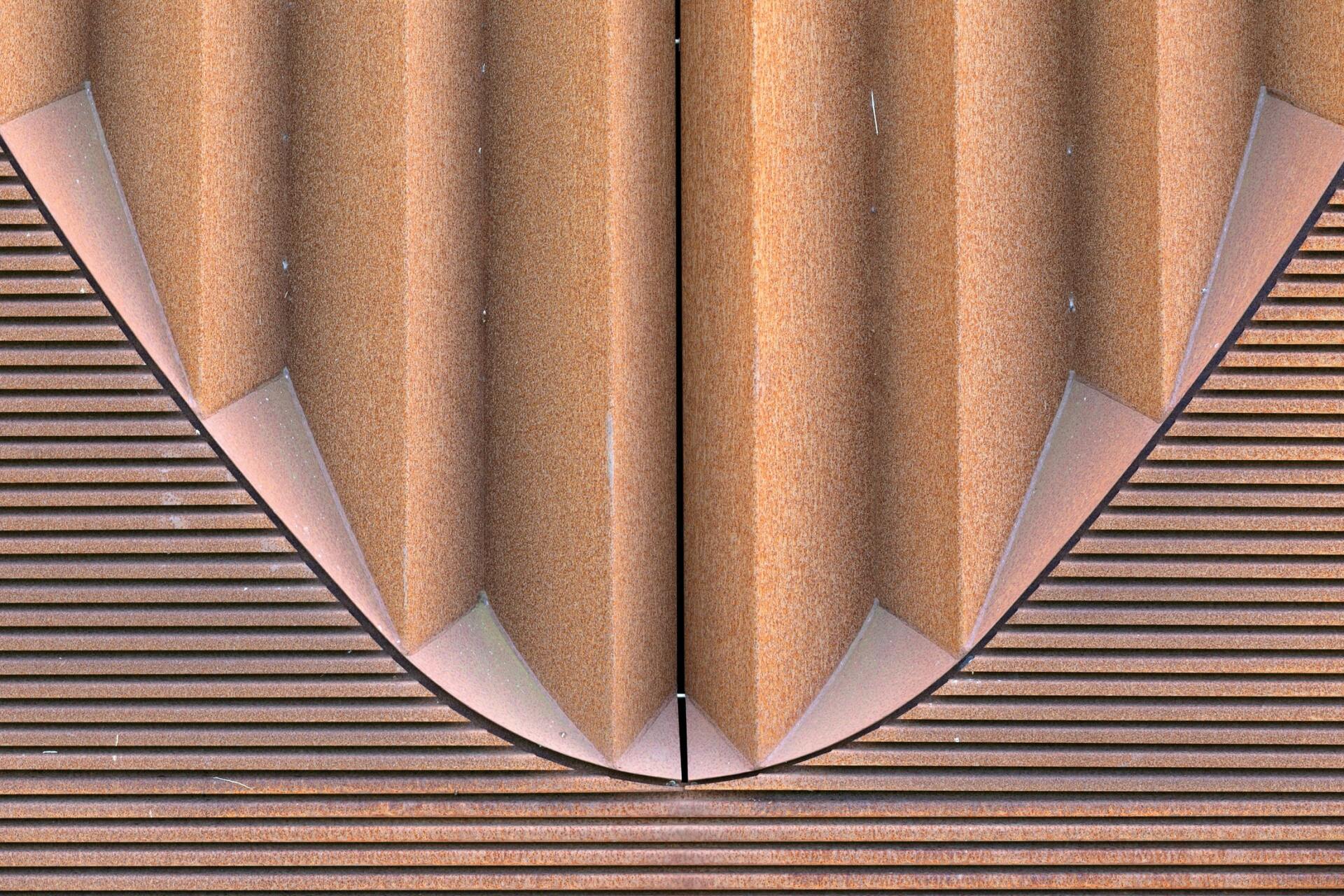

You can choose from many roof panel styles. Corrugated metal roofs have been around the longest and feature a kind of wave pattern. These are commonly seen on older barns or sheds, but they are typically not recommended for urban areas. Today roof panels are often galvanized and highly durable.

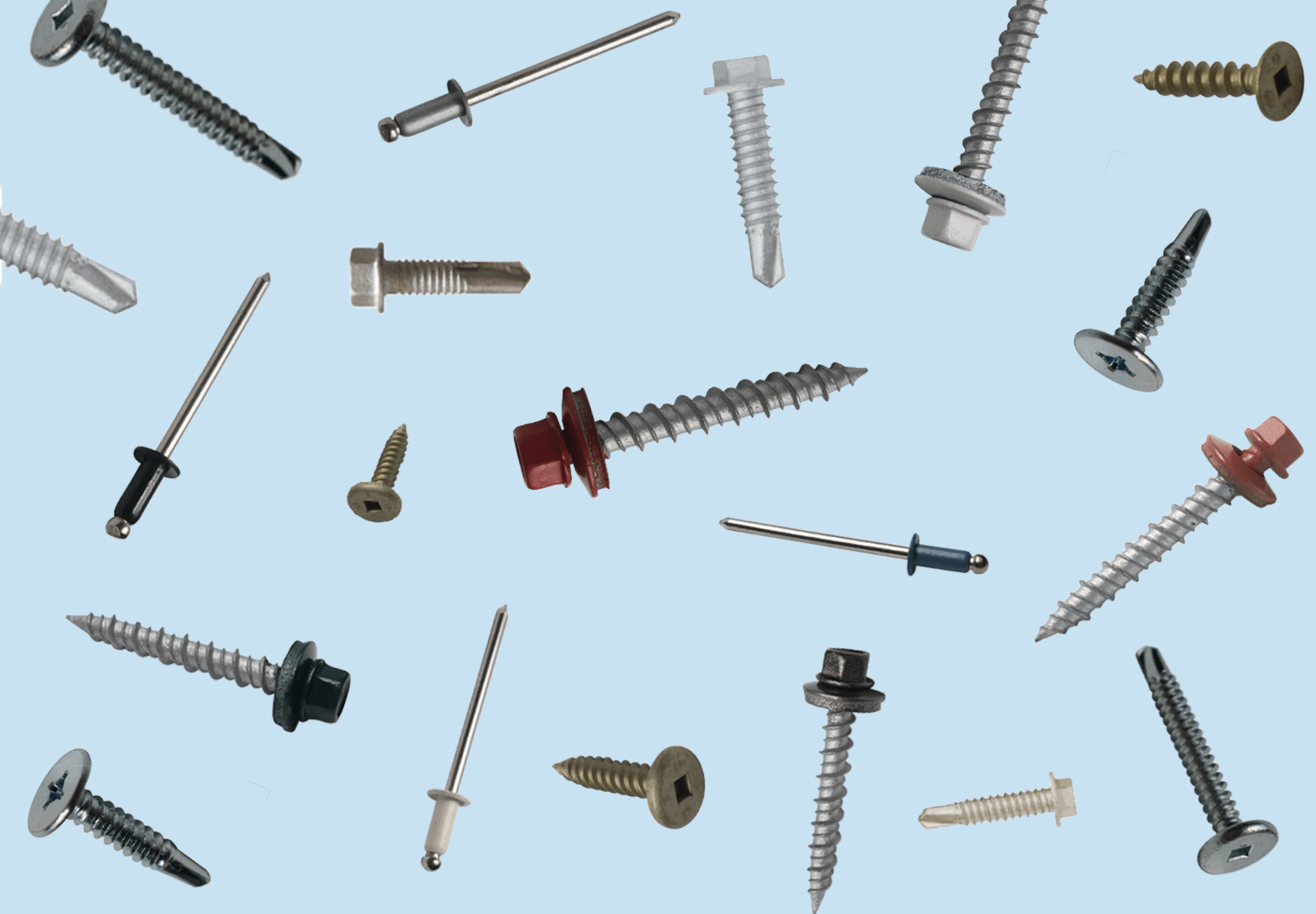

We prefer a concealed fastener roofing panel and system. This design conceals the fasteners (screws) from the elements greatly reducing erosion from water over the life of the roof.

Locking panel systems are linked with vertical seams. For installation your contractors will snap or bend the edges of the panels together. This creates a uniform roof that is much stronger than other metal roof options and better able to withstand rain and high winds. There are three types of locking mechanisms: snap-loc, single and double-lock.

With a snap-loc system, you place a metal panel on the roof and screw it into place. The first panel has an edge component that fits tightly into the edge of the subsequent, overlapping panel. These panels are snapped into place using hand pressure or a gentle blow from a rubber mallet. The system holds the panels tightly in place and covers up the screws that are placed beneath the locking panel juncture.

Single-Lock

With single-lock metal roof panels, the primary seam has a vertical lip on the end of the panel with an edge that extends back toward the panel side. The subsequent panel has a similar edge that is slightly taller, with an edge that extends out in the direction of the existing panel and down.

Once the panel is placed, the two lips sit on top of each other. Finally, your installation crew must bend the lip of the second panel using a special tool, so the top lip curves beneath the lip of the bottom panel. This creates a very secure system and can be used even on roofs with a steep pitch.

For a double-lock panel, you do the same procedure as the single lock. Once the two lips have been bent together, you make another pass along the seam and provide a further bend to ensure an even tighter linkage. Double-loc is most often used on roofs that have a 3/12 pitch or less.

Color is more than just a cosmetic decision as you design your new metal roof. White or off-white roofs can reflect away the sun’s energy and allow your house to stay cool without the use of air conditioning.

Some estimates have shown that white or off-white roofs can create anywhere from an 18% to 26% reduction in energy consumption. Choosing a white or off-white roof can offer considerable monthly savings that will last you for the entire lifetime of the roof.

Installing a new roof requires a lot of material, and this can create a logistical problem for project managers. Shipping costs can be prohibitive, and the material has to be stored on-site until your installation crew needs it.

Shipping of the panels can also lead to loss, damage & even shipment delays. Instead of traditional ordering and shipping, it is more efficient and economical to have your panels rolled on site. This allows your crew to have exactly the material they need when they need it and eliminates handling and shipping issues.

What Is On-Site Rolling?

On-site rolling utilizes a special machine that is brought to the site on a trailer. The machine can form metal that is rolled up on a coil into the exact panel size and shape that you need. This means that your installation crew can take the perfect panel right from the machine and directly to your roof. The coils are much easier to ship & handle and are much less likely to be damaged in transport.

No Stacks of Panels

On-site rolling means that you won’t have large stacks of panels sitting in your yard and killing your grass. Also, the direct creation of panels reduces the handling time of moving panels around and repeatedly stacking them. Finally, there will be no delays as you wait for shipments of prefabricated panels that are traveling from off site and are subject to traffic and weather delays.

In order to have the perfect roof, you need the perfect material formed to the perfect size. Some roofs have lots of valleys and angles that can become complicated to cover and require specially cut panels. With on-site rolling, you can be assured that your installation crew will always have the perfect component to finish the job.

On-site rolling provides the assurance that your installation crew will not be forced to make do with a panel that is just a close fit. Instead, you will have perfect, custom-created panels on every square inch of your roof.

Ask For a Quote Today

There are many things you should look for when you are shopping for metal roof panels. Determine the right gauge panels for your needs. Then, consider the type of panels you want, the best locking system for your purposes, and the pitch of your roof. Last but not least, consider whether you live in an area where your color choice could provide you with considerable savings on your energy consumption.

The capacity for on-site rolling is also a huge consideration for metal roof panels. On-site rolling is more efficient and affordable and provides an assurance that every roof panel with be a perfect, custom fit. If you have more questions about metal roof panels or you would like to receive a quote, contact Hill Country Metal Roofing Supply today. With on-site rolling and a variety of panel styles and colors, Hill Country Metal Roofing Supply is a one-stop-shop for your perfect metal roof.

Choosing to install a metal roof is an excellent decision for numerous reasons, including the fact that it will last much longer than a traditional roof, is more energy-efficient, and is better for the environment. However, there are some accessories that are highly recommended for your metal roof that will help make it more effective. These nine metal roof accessories will not only greatly enhance your roof's effectiveness, but will also increase its durability as well.

How heavy is a metal roof? You might be surprised to learn that it is one of the lightest options. Metal roofs are lighter than asphalt shingles, clay & concrete tiles. The weight of 26-gauge metal roofing is approximately just under one pound per square foot. The weight of 24-gauge metal roofing is about 1.15 pounds. The lower the gauge of the metal, the thicker and heavier the material will be.