8 Uses for Butyl Tape and Where to Find it

February 10, 2020

Supply Delivery

Get A Free Quote Today!

Selecting the correct sealant and adhesive will often determine the ultimate success of your task. Adhesives can be sorted into one of three categories: rubber-based, acrylic-based, or silicon-based. Each variety of adhesive has its own set of pros and cons. Selecting the adhesive category that matches the substrate you hope to bond is the secret to a successful outcome. For this article, we will be focused on butyl tape, a subset of the rubber-based adhesive category.

What Is Butyl Tape?

This tape is a synthetic, rubber, pressure-sensitive adhesive (PSA) tape formulated in the lab rather than crafted from natural rubber tree resins. Rubber adhesives have a high initial tack, which means it is very sticky and adheres to most surfaces instantly. The high level of adhesion and flexibility of butyl tape makes it a good choice for bonding applications where moisture is an issue or the surfaces to be bonded are smooth and non-porous like metal or glass.

Pros

Cons

3) Butyl tape does not adhere well to uneven, rough surfaces

Is This Tape Always the Same Size?

Butyl synthetic rubber adhesive comes in an endless array of shapes, sizes, and thicknesses. The flexibility of the material makes it simple to customize the product dimensions to the optimum fit for the application. Generally, you can find it in these sizes:

Solid butyl sealing cord ranging in size from 2mm to 80mm in diameter.

Butyl sealing cord with cotton, foam, or rubber core, ranging in size from 4mm to 20 mm in diameter

Flat tape ranging in thickness from 0.8mm to 30mm and ranging in width from 3mm to 500mm

Laminated tape with an aluminum foil, mesh, or woven substrate impregnated with butyl adhesive from 0.4mm to 3mm thick

The most common form used in the United States, and the most widely available, is the double-sided butyl tape roll. Butyl rolls are sold individually or in multi-packs and are most frequently offered in the following common dimensions:

1/2 inch wide and 1/16 inches thick on rolls from 35 to 100 feet

3/4 inch wide and 1/16 inches thick on rolls from 35 to 100 feet

3/4 inch wide and 1/8 inches thick on rolls from 35 to 100 feet

1 inch wide and 1/8 inches chick on rolls from 35 to 100 feet

#1

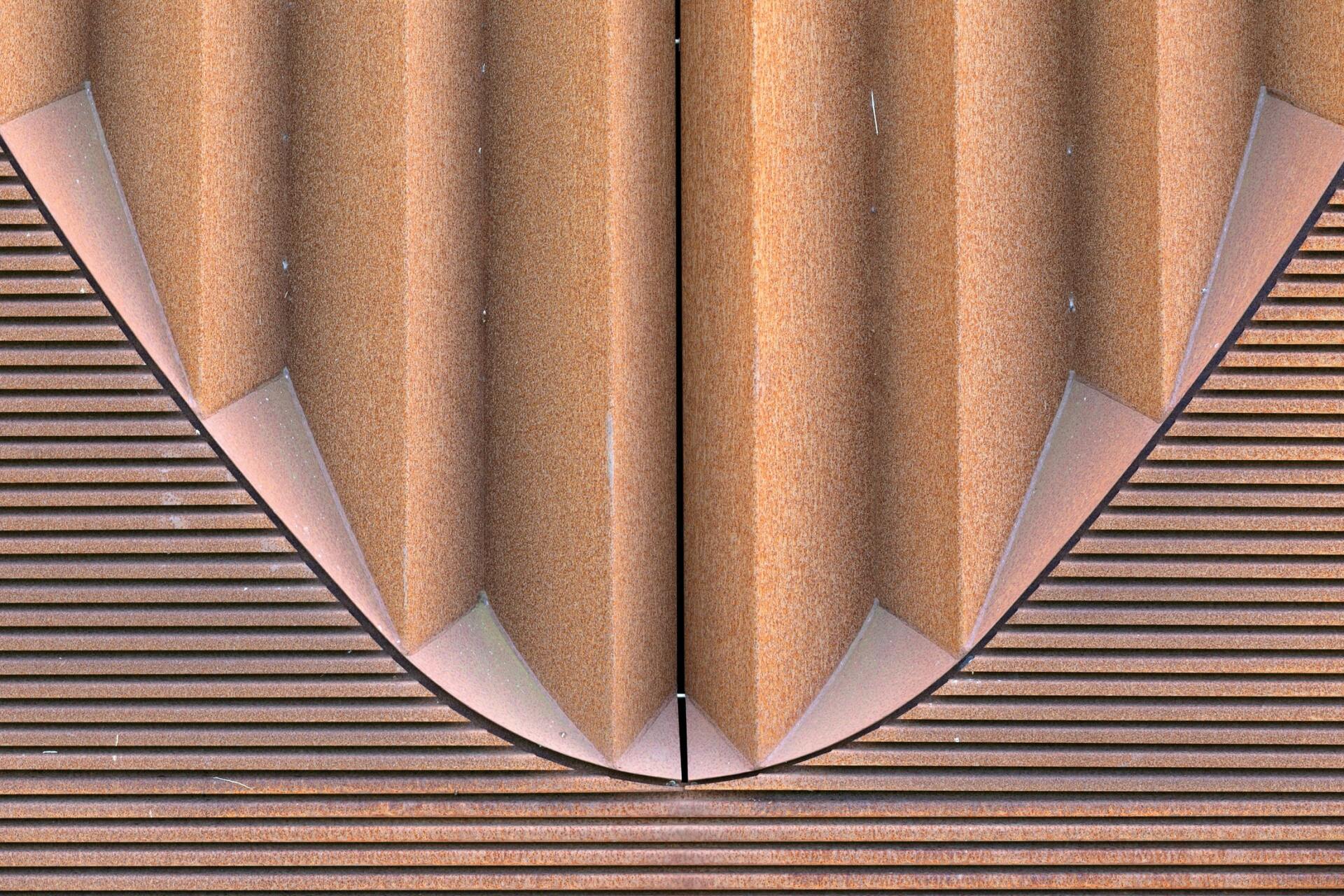

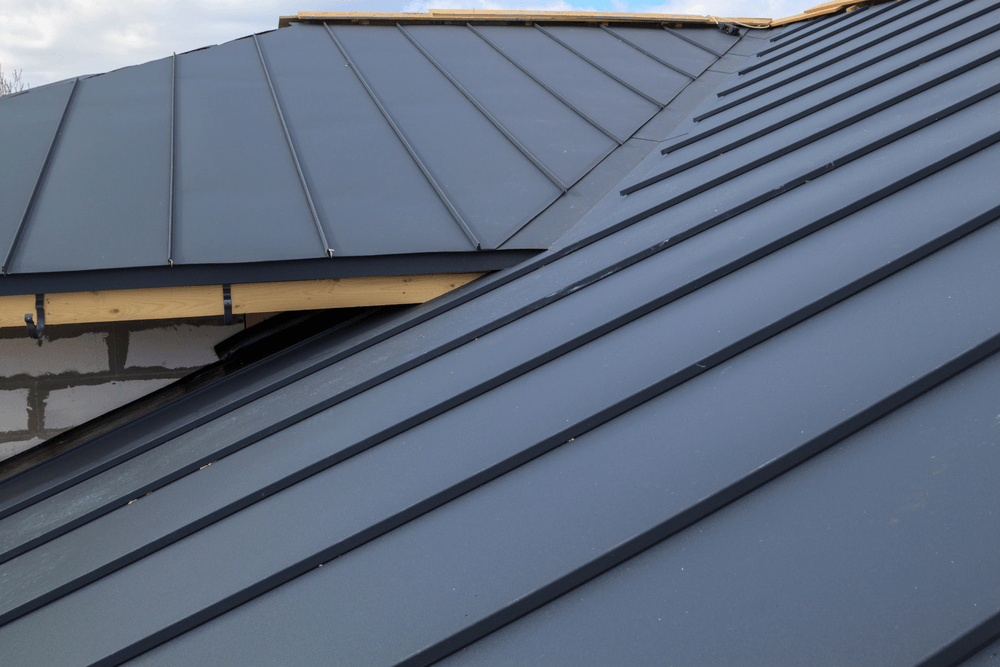

Creating a Waterproof Seal Between Metal Roofing or Metal Siding Panels

Butyl synthetic rubber adhesive is designed to provide a secure seal between metal panels in metal roofing and metal siding applications. When installed between each panel overlap, butyl tape forms an effective weather barrier against moisture, dirt, air, and allergens.

#2 Replace Original Sealant Around RV Windows

The original putty sealing medium used during the installation of doors and windows in older RVs and travel trailers was a non-butyl putty, which turns hard and brittle with regular exposure to UVA from sunlight and cold winter weather. Once the original seal becomes hard and brittle, it can no longer provide an effective weather barrier, and, if left unprotected, will allow moisture to seep into the interior portion of the RV, causing significant water damage to the interior walls.

You will need to physically remove each individual window to replace the original degraded putty seals with a fresh butyl synthetic rubber adhesive seal. The process is not complicated, but you will need a helper posted on the opposite side of the glass during the removal process to prevent the window from falling from the opening. You should be able to remove the windows in most RVs or travel trailers with a simple screwdriver and a healthy amount of patience.

How to Use

Locate and remove all the screws securing the window frame to the RV or trailer wall

Loosen and remove any original putty if required and carefully lift window out of the wall opening

Clean window frame thoroughly and wipe down with isopropyl alcohol to remove any built-up grime

Apply the double-sided tape to the interior surface of the window frame

Remove the paper backing to expose the second adhesive side

Seat the window back in place making sure the tape remains securely in place between the window frame and the wall

Replace the screws and tighten to secure

#3 Create a Waterproof Seal When Installing Vents, Wiring, or Pipes

Butyl synthetic rubber adhesive makes an excellent watertight barrier when installing vents, ducting, plumbing, or electrical conduit that requires breaching the structure's original outer cladding. An application of tape between the flashing and the existing metal roofing or siding during the installation process will help ensure the weather-tight integrity of the outer shell remains robust.

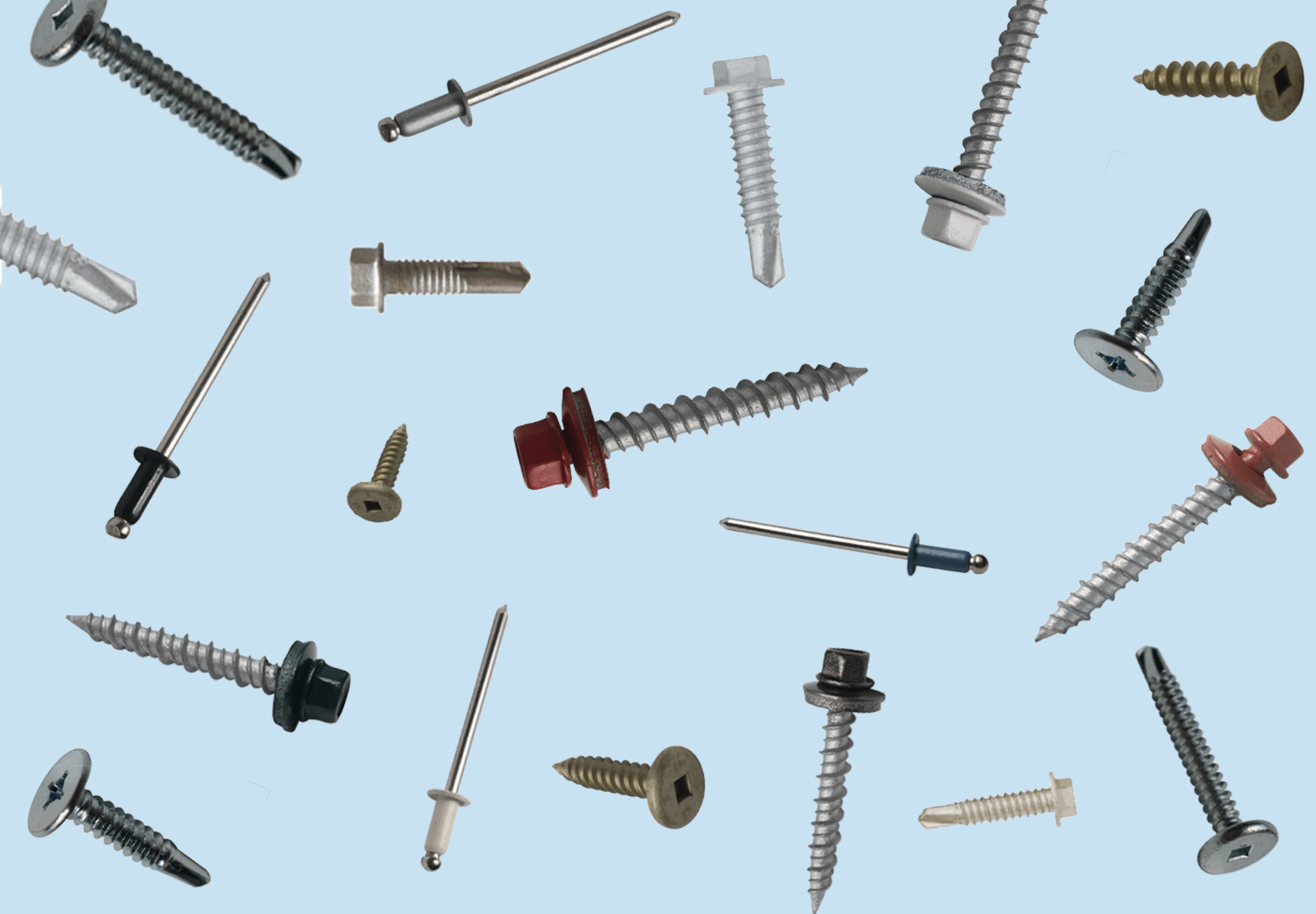

#4 Seal Screw and Bolt Entry Points

It is easy to overlook the entry points created by each individual fastener, but these are common entry points for moisture to seep in. These incursions are small and hidden from sight behind interior wall panels, so they often go undetected until the water damage is substantial enough to be seen on the interior walls.

It is not practical to seal all existing fasteners, but if there are obvious problem areas, it is possible to prevent any further water seepage by removing the offending fasteners, covering the entry point with a small piece of tape and reinserting the fastener through the tape to form a watertight seal.

#5 Create Waterproof Seal When Bedding Ports, Hardware, or Equipment to Marine Craft

Prevent water damage to your boat's wooden surfaces when bedding portholes, hatches, windows, or hardware. The bedding process seals the new addition to the surrounding surface and prevents water from seeping into the wood through the fastener points and causing softening and rot. This can be accomplished by applying butyl synthetic rubber adhesive between the original surface and the new installation before securing it using hardware.

#6 Apply Between Joists and Flashing on Deck Construction Projects

Apply one of the wider tape varieties to the end of each joist during the construction of a new deck or balcony. The tape acts as a protective barrier between the metal joist support or home flashing and the wood of the joist. This barrier helps keep moisture that has accumulates at these normal condensation points from seeping into the wood joists. The dryer you are able you keep your wooden deck's support joists, the longer your deck will remain safe and beautiful.

#7 Adhere Moisture Barrier to Masonry Walls of Crawlspace or Cellar

While the focus of most butyl synthetic rubber adhesive discussion is the applicability in metal to metal applications, it is worth noting that this tape also adheres to masonry and plastics remarkably well. This makes the tape an excellent option for securing a plastic moisture barrier or foam insulation panels to the masonry walls of a crawlspace, basement, or cellar.

You will need to clean any excess dirt or debris off the masonry surface using a scrub brush to ensure a strong bond between the tape and the masonry surface.

#8 Seal Metal Ductwork In a Climate Control System

Butyl synthetic rubber adhesive makes an excellent air-tight seal for connecting lengths of metal ducting to route airflow throughout a residence or commercial building for climate control system

Not All Butyl Tape Is Created Equal

It's important to note that not all adhesives are created equal—the same goes with butyl tape. If you find cheaper options online, be wary. When it comes to keeping out moisture, no matter the project, it's critical that your tape is doing the job it's intended for. When you're buying supplies for any major project, it's important to ensure that you trust the manufacturer, or at the very least, your supplier!

Hill Country Roofing Supply

No matter what your project is, there are several options available when you are ready to purchase butyl tape for your project. When you need butyl synthetic rubber adhesive tape for your roofing project or need other materials, especially for installing a metal roof, contact the experts at Hill Country Metal Roofing Supply!

You Order! We Deliver! We also offer metal panels and many other roofing accessories. Everything is delivered directly to your job site—all accessories and panels rolled on-site. If you run short on materials, we can have that material to you the same or next day in most cases. Call us today for your next big project!

Get A Free Quote Today!

What Is Butyl Tape?

This tape is a synthetic, rubber, pressure-sensitive adhesive (PSA) tape formulated in the lab rather than crafted from natural rubber tree resins. Rubber adhesives have a high initial tack, which means it is very sticky and adheres to most surfaces instantly. The high level of adhesion and flexibility of butyl tape makes it a good choice for bonding applications where moisture is an issue or the surfaces to be bonded are smooth and non-porous like metal or glass.

Pros & Cons of This Adhesive

1) Butyl synthetic rubber adhesive is more affordable than acrylic or silicone adhesive option

2) High degree of adhesion allows butyl tape to bond instantly and securely to even resistant surfaces

3) Butyl synthetic rubber adhesive is less temperature sensitive and more UVA resistant than natural rubber adhesive products

4) Butyl synthetic rubber adhesive provides a long-lasting, effective barrier that is both water and airtight

5) Butyl synthetic rubber adhesive is flexible and able to maintain a secure seal through moderate substrate expansion and contraction

movements

Cons

1) Butyl tape is solvent-based and dissolves when exposed to stronger solvents like mineral oil, gasoline, turpentine, and other common

solvents

2) Though temperature and light sensitivity has improved drastically in butyl tape, it is still susceptible and should not be used in extreme

conditions

Is This Tape Always the Same Size?

Butyl synthetic rubber adhesive comes in an endless array of shapes, sizes, and thicknesses. The flexibility of the material makes it simple to customize the product dimensions to the optimum fit for the application. Generally, you can find it in these sizes:

Solid butyl sealing cord ranging in size from 2mm to 80mm in diameter.

Butyl sealing cord with cotton, foam, or rubber core, ranging in size from 4mm to 20 mm in diameter

Flat tape ranging in thickness from 0.8mm to 30mm and ranging in width from 3mm to 500mm

Laminated tape with an aluminum foil, mesh, or woven substrate impregnated with butyl adhesive from 0.4mm to 3mm thick

The most common form used in the United States, and the most widely available, is the double-sided butyl tape roll. Butyl rolls are sold individually or in multi-packs and are most frequently offered in the following common dimensions:

1/2 inch wide and 1/16 inches thick on rolls from 35 to 100 feet

3/4 inch wide and 1/16 inches thick on rolls from 35 to 100 feet

3/4 inch wide and 1/8 inches thick on rolls from 35 to 100 feet

1 inch wide and 1/8 inches chick on rolls from 35 to 100 feet

8 Projects Where This Tape Excels

Butyl synthetic rubber adhesive is designed to provide a secure seal between metal panels in metal roofing and metal siding applications. When installed between each panel overlap, butyl tape forms an effective weather barrier against moisture, dirt, air, and allergens.

#2 Replace Original Sealant Around RV Windows

The original putty sealing medium used during the installation of doors and windows in older RVs and travel trailers was a non-butyl putty, which turns hard and brittle with regular exposure to UVA from sunlight and cold winter weather. Once the original seal becomes hard and brittle, it can no longer provide an effective weather barrier, and, if left unprotected, will allow moisture to seep into the interior portion of the RV, causing significant water damage to the interior walls.

You will need to physically remove each individual window to replace the original degraded putty seals with a fresh butyl synthetic rubber adhesive seal. The process is not complicated, but you will need a helper posted on the opposite side of the glass during the removal process to prevent the window from falling from the opening. You should be able to remove the windows in most RVs or travel trailers with a simple screwdriver and a healthy amount of patience.

How to Use

Locate and remove all the screws securing the window frame to the RV or trailer wall

Loosen and remove any original putty if required and carefully lift window out of the wall opening

Clean window frame thoroughly and wipe down with isopropyl alcohol to remove any built-up grime

Apply the double-sided tape to the interior surface of the window frame

Remove the paper backing to expose the second adhesive side

Seat the window back in place making sure the tape remains securely in place between the window frame and the wall

Replace the screws and tighten to secure

#3 Create a Waterproof Seal When Installing Vents, Wiring, or Pipes

Butyl synthetic rubber adhesive makes an excellent watertight barrier when installing vents, ducting, plumbing, or electrical conduit that requires breaching the structure's original outer cladding. An application of tape between the flashing and the existing metal roofing or siding during the installation process will help ensure the weather-tight integrity of the outer shell remains robust.

#4 Seal Screw and Bolt Entry Points

It is easy to overlook the entry points created by each individual fastener, but these are common entry points for moisture to seep in. These incursions are small and hidden from sight behind interior wall panels, so they often go undetected until the water damage is substantial enough to be seen on the interior walls.

It is not practical to seal all existing fasteners, but if there are obvious problem areas, it is possible to prevent any further water seepage by removing the offending fasteners, covering the entry point with a small piece of tape and reinserting the fastener through the tape to form a watertight seal.

#5 Create Waterproof Seal When Bedding Ports, Hardware, or Equipment to Marine Craft

Prevent water damage to your boat's wooden surfaces when bedding portholes, hatches, windows, or hardware. The bedding process seals the new addition to the surrounding surface and prevents water from seeping into the wood through the fastener points and causing softening and rot. This can be accomplished by applying butyl synthetic rubber adhesive between the original surface and the new installation before securing it using hardware.

#6 Apply Between Joists and Flashing on Deck Construction Projects

Apply one of the wider tape varieties to the end of each joist during the construction of a new deck or balcony. The tape acts as a protective barrier between the metal joist support or home flashing and the wood of the joist. This barrier helps keep moisture that has accumulates at these normal condensation points from seeping into the wood joists. The dryer you are able you keep your wooden deck's support joists, the longer your deck will remain safe and beautiful.

#7 Adhere Moisture Barrier to Masonry Walls of Crawlspace or Cellar

While the focus of most butyl synthetic rubber adhesive discussion is the applicability in metal to metal applications, it is worth noting that this tape also adheres to masonry and plastics remarkably well. This makes the tape an excellent option for securing a plastic moisture barrier or foam insulation panels to the masonry walls of a crawlspace, basement, or cellar.

You will need to clean any excess dirt or debris off the masonry surface using a scrub brush to ensure a strong bond between the tape and the masonry surface.

#8 Seal Metal Ductwork In a Climate Control System

Butyl synthetic rubber adhesive makes an excellent air-tight seal for connecting lengths of metal ducting to route airflow throughout a residence or commercial building for climate control system

Not All Butyl Tape Is Created Equal

It's important to note that not all adhesives are created equal—the same goes with butyl tape. If you find cheaper options online, be wary. When it comes to keeping out moisture, no matter the project, it's critical that your tape is doing the job it's intended for. When you're buying supplies for any major project, it's important to ensure that you trust the manufacturer, or at the very least, your supplier!

Hill Country Roofing Supply

No matter what your project is, there are several options available when you are ready to purchase butyl tape for your project. When you need butyl synthetic rubber adhesive tape for your roofing project or need other materials, especially for installing a metal roof, contact the experts at Hill Country Metal Roofing Supply!

You Order! We Deliver! We also offer metal panels and many other roofing accessories. Everything is delivered directly to your job site—all accessories and panels rolled on-site. If you run short on materials, we can have that material to you the same or next day in most cases. Call us today for your next big project!

Choosing to install a metal roof is an excellent decision for numerous reasons, including the fact that it will last much longer than a traditional roof, is more energy-efficient, and is better for the environment. However, there are some accessories that are highly recommended for your metal roof that will help make it more effective. These nine metal roof accessories will not only greatly enhance your roof's effectiveness, but will also increase its durability as well.

How heavy is a metal roof? You might be surprised to learn that it is one of the lightest options. Metal roofs are lighter than asphalt shingles, clay & concrete tiles. The weight of 26-gauge metal roofing is approximately just under one pound per square foot. The weight of 24-gauge metal roofing is about 1.15 pounds. The lower the gauge of the metal, the thicker and heavier the material will be.